The LL330 Series provides a sealed high intensity line light solution for demanding industrial environments. Engineered to withstand harsh conditions, these line lights are completely protected from dust and debris, ensuring reliable performance where other lights fail. In addition, passive thermal management eliminates the need for active cooling fans, contributing to low-maintenance, long-term operation.

The LL330 is available with an embedded control option, designed for continuous operation and housed within the configured light head. With options for converging or collimating optics, this series is suited for a variety of application needs. The LL330 is ideal for sheetrock, lumber, ceramics, stone, and other industries utilizing line scan imaging where airborne particulate, dust, and debris are concerns.

- SPECIFICATIONS

- MECHANICAL

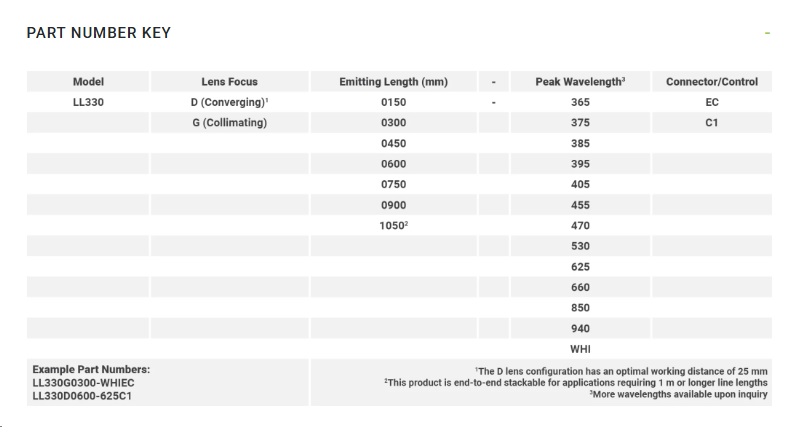

- OPTICAL PERFORMANCE

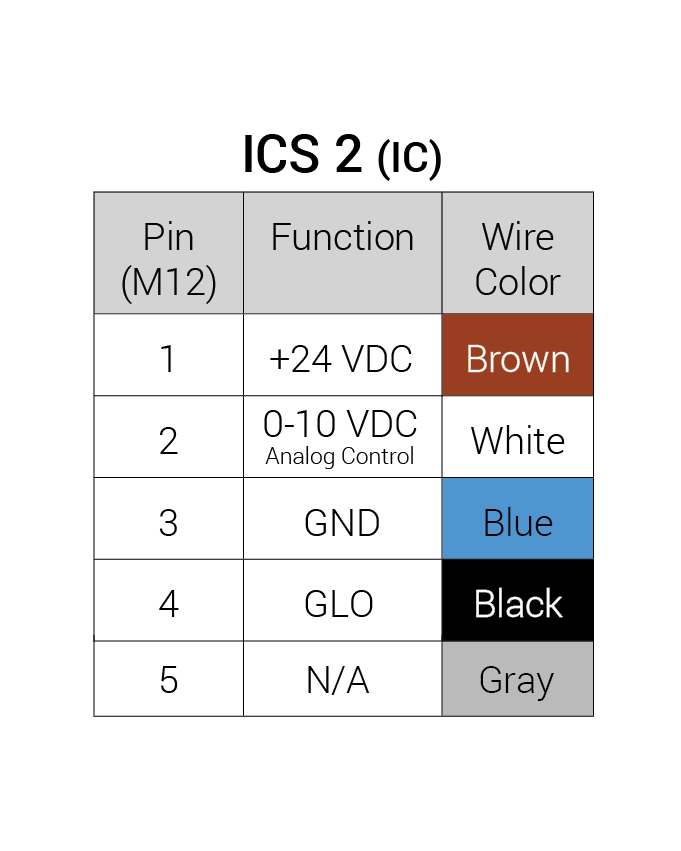

- ELECTRICAL

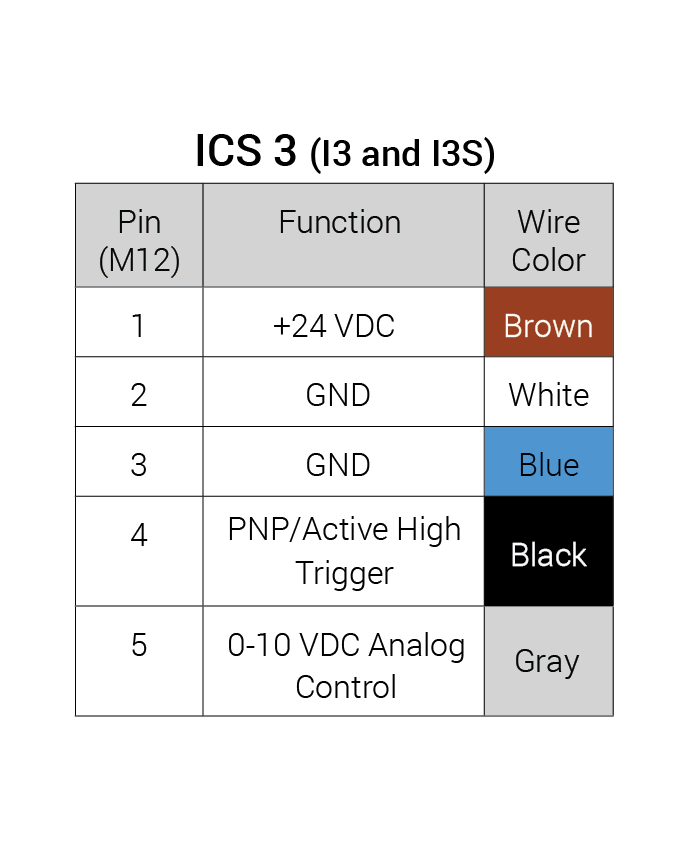

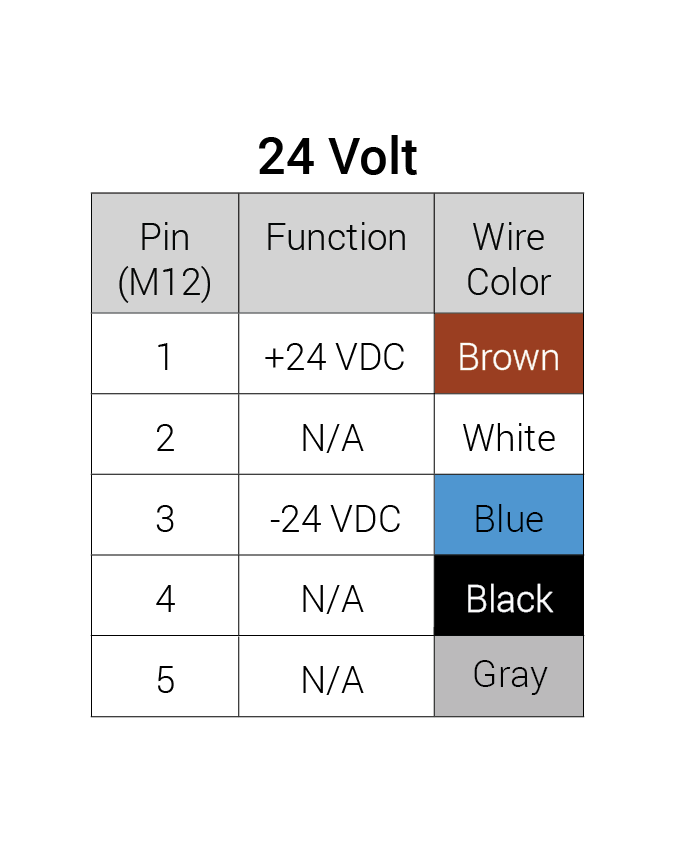

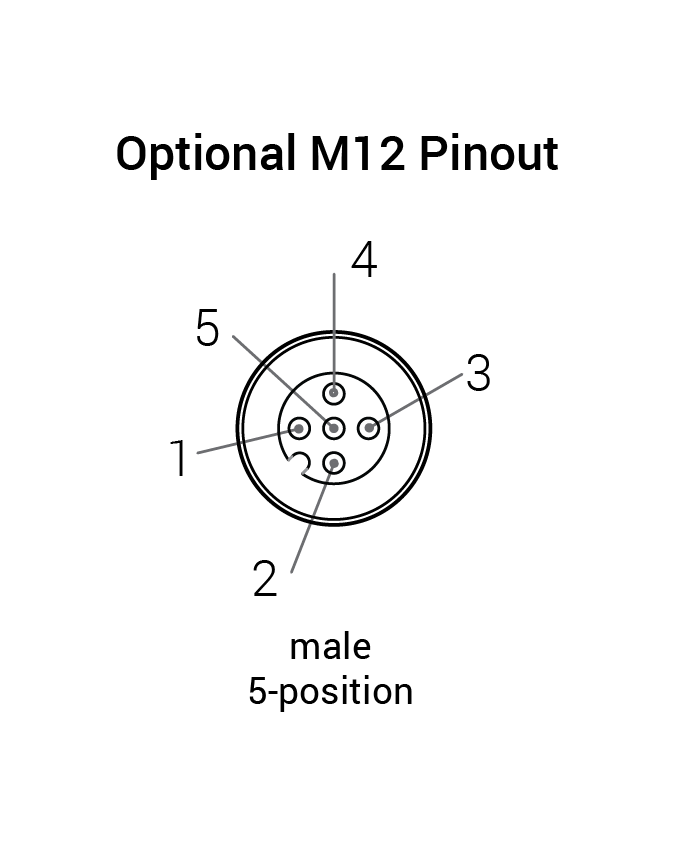

- CONTROL SPECS

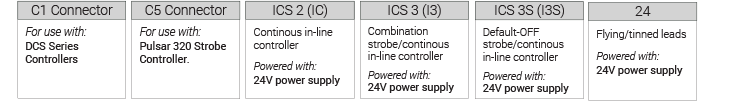

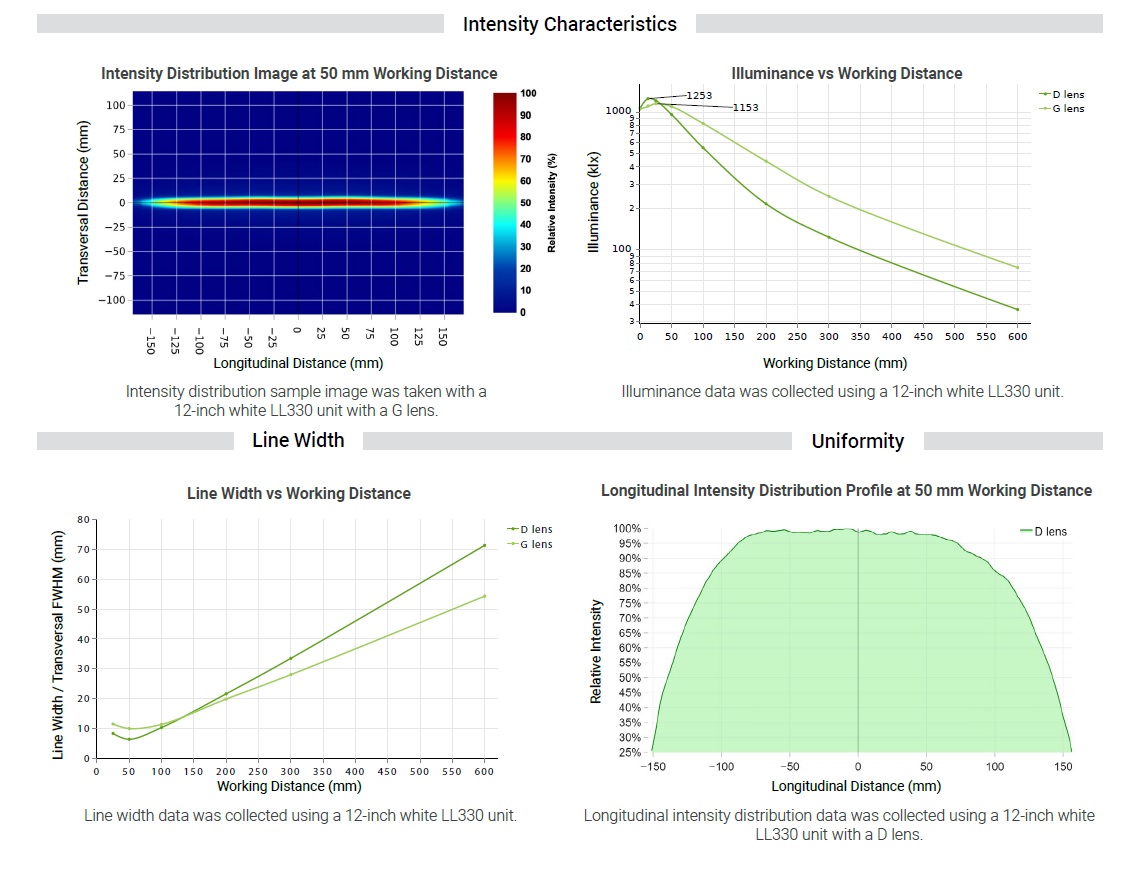

- PART NUMBER GUIDE

- DOWNLOADS

CURRENT | COLOR | 24VDC Current | All Other Controls |

| White, 455, 470, 530, 625, 850, 940 | 500 mA per 100 mm segment | 500 mA per 100 mm segment |

| OPERATING TEMPERATURE | 0 to 60°C |

| MASS | 1,442 g (3.i8 lb) per 300 mm length |

| INCLUDED CABLE | 2 M long -0/+150 mm (80″ -0/+6″) – 105°C rated PVC jacket, foil shield with drain |

| PHOTOBIOLOGICAL SAFETY | Exempt Applicable Wavelengths: 850, 940 Group 1 (Low-Risk) Applicable Wavelengths: 455, 660, 730, WHI |

| STANDARDS COMPLIANCE | CE, RoHS, IEC 62471 |

| IP RATING | IP67 |

| LUMINANCE MAINTENANCE | L70 = 50,000 Hours |

|  |  |  |