Key features:

- Integrates encoders, cameras, lighting, proximity sensors, reject gates

- Fast and simple set up – no complicated programming routines

- Ethernet enabled for remote interfacing

- Fast and accurate timing functions

- Small compact size

- A true single component solution for machine vision integration applications

- Camera trigger timing

- Reject gate timing

- Remote digital input and output

Examples

Video

| CC320 Specifications | |

|---|---|

| Digital Inputs | 8 inputs |

| Digital Outputs | 8 Outputs |

| Configuration Interface | Ethernet – TCP/IP or web browser or pushbutton and display |

| Digital Input Format | Common cathode opto input 5V to 24V at 3mA to 20mA |

| Digital Output Format | Open collector, switching 24V and 20mA |

| Supply Voltage | Regulated 24V to 48V |

| Dimensions | 146 mm long x 49 mm wide x 24 mm high |

| Weight | 200g |

| Mounting | DIN rail or Panel Mounting |

When combining lighting, cameras, proximity sensors and encoders to generate an automated solution, the CC320 Trigger Timing Controller is the single component for fast affordable integration. With 8 independent input channels, the controller can take a range of input signals from various components and use these to trigger events on any of the 8 independent output channels.

Each of the 8 output channels can be individually programmed offering complete control over the pulse delay and pulse width, as well as a trigger delay enabling filtering of noisy trigger signals. In applications where encoders are connected to the input channels, outputs can be configured as functions of encoder pulses rather than absolute time values, creating a very versatile solution.

Ethernet enabled as standard, the CC320 can be quickly configured using our free software which can be downloaded from this page, or even simply by accessing the controller via your internet browser; type in the IP address for the controller into your browser and you have full access to all of the parameters. If you are using a third party software package the CC320 has a simple command set that is detailed in the manual allowing easy communication. As will all Gardasoft products, all the settings are stored in non-volatile memory, and it will retain these settings even when the Ethernet connection is disconnected. The different ways the CC320 can be configured is endless.

To give you an idea of how the CC320 can be utilized, please take a look at application note 937 which can be found from the downloaded link opposite. This application note highlights just some of the ways in which the CC320 has been utilized within machine vision applications.

Examples

Machine Vision Timing Controller – application examples

On the CC320 there are 8 digital inputs labelled IP1 to IP8, and 8 digital outputs labelled OP1 to OP8. Each output can perform any function. Some application examples are presented below.

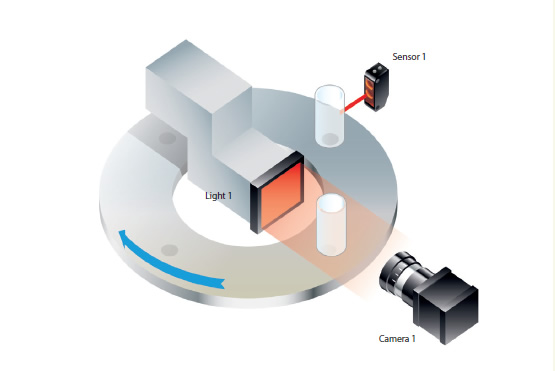

| Delayed Signal modeDelayed output following the detection of products Example 1 – Principle of operationA product sensor provides a signal when a product is present. This signal needs to be delayed so that an inspection light is only turned on when a product is present. The delay can be a time or a number of encoder counts. After Sensor 1 detects a product, there is a delay of 500ms before Light 1 is turned on. |

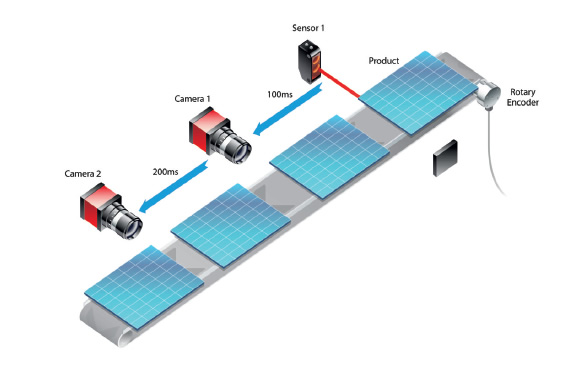

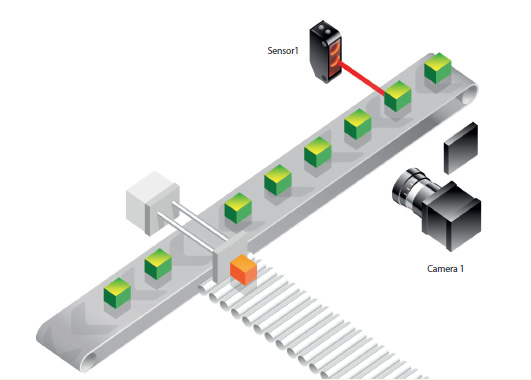

| Delayed Signal modeDelayed output following the detection of products – based on timing Example 2 – Constant belt speedA sensor detects product presence, these products are evenly spaced on a guided rail. There are two cameras which need to take an image after different delays. The leading edge of Sensor 1 is used as the trigger: – OP1 triggers Camera 1 after 100ms |

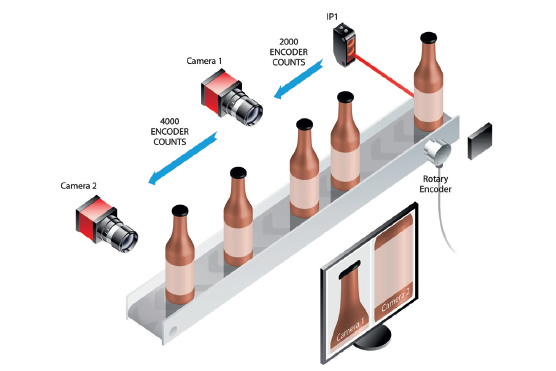

| Delayed Signal modeDelayed output following the detection of products – based on distance Example 3 – Variable belt speedOn a conveyor with an encoder, a sensor detects product presence. There are two cameras which need to take an image at fixed distances along the belt. The camera trigger pulses must be fixed width for exposure control. The trailing edge of Sensor 1 is used as the trigger. OP1 triggers the first camera after 2000 encoder counts. OP2 triggers the second camera after 4000 encoder counts. By using encoders, the image will be captured correctly even if the conveyor changes speed. |

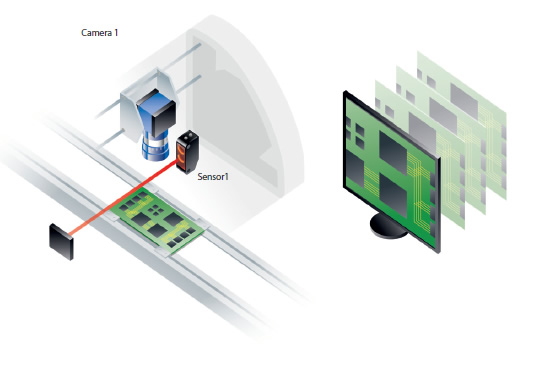

| Gated Pulse modeWhere an output is required at a fixed frequency whenever a product is present. A camera needs to be triggered at 25Hz continuously, except when Sensor 1 is high to indicate that there is no product present or the machine has stopped. Camera 1 is triggered on OP1, and will trigger continuously at 25Hz – only when Sensor 1 is low. The 25Hz trigger is generated by the internal timer. |

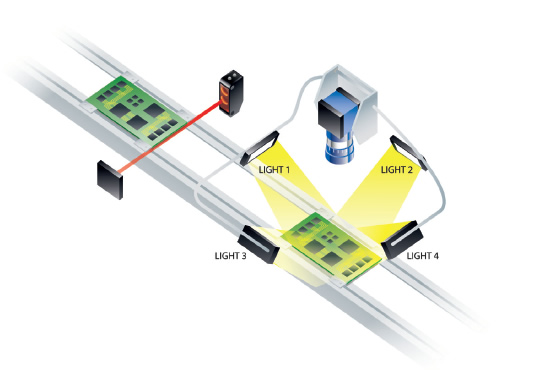

| Pulse Burst modeMultiple outputs are required from one trigger signal In this example, a sensor on IP1 detects product presence. Four images need to be taken from one camera using four different lights at 40ms intervals. OP1, OP2, OP3, OP4 are used to output triggers to turn on the four lights in sequence. OP5 is used to trigger the camera four times. OP1 to OP4 are pulsed for 40ms in sequence. As each one is pulsed, OP5 is also pulsed for a short time to trigger the camera. |

| FIFO modeA FIFO shift register function for reject synchronisation At the end of the belt is a reject gate connected to OP2. The timing for the reject gate must be synchronised to the original sensor, not to when the image processing gives pass/fail. There might be multiple products between the sensor and reject gate. These products are individually tracked by the CC320 so that they are accepted or rejected at the correct time. |

Video